|

|

|

|

| Pulley Products | | |  |  |  |  |  | | | | Arc tooth Timing tooth

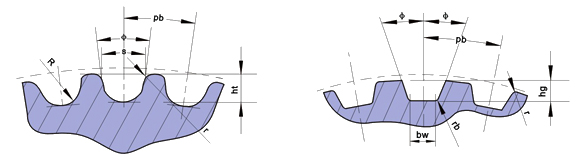

| | Type | pb | hg | R | r1 | s | 2¦Ä | łÝĐÎ˝Ç | | 3M | 3 | 1.28 | 0.91 | 0.26ˇ«0.35 | 1.90 | 0.762 | ˇÖ14ˇă | | 5M | 5 | 2.16 | 1.56 | 0.48ˇ«0.52 | 3.25 | 1.144 | ˇÖ14ˇă | | 8M | 8 | 3.54 | 2.57 | 0.78ˇ«0.84 | 5.35 | 1.372 | ˇÖ14ˇă | | 14M | 14 | 6.20 | 4.65 | 1.36ˇ«1.50 | 9.80 | 2.794 | ˇÖ14ˇă | | 20M | 20 | 8.60 | 6.84 | 1.95ˇ«2.25 | 14.80 | 4.320 | ˇÖ14ˇă | | | | Dimension of linear type pulley

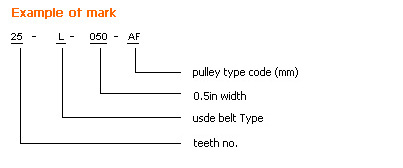

| | Type | MXL | XXL | XL | L | H | XH | XXH | | bw | 0.84ˇŔ0.05 | 1.14ˇŔ0.05 | 1.32ˇŔ0.05 | 3.05ˇŔ0.10 | 4.19ˇŔ0.13 | 7.90ˇŔ0.15 | 12.17ˇŔ0.18 | | hg | 0.69 | 0 | 0.84 | 0 | 1.65 | 0 | 2.67 | 0 | 3.05 | 0 | 7.14 | 0 | 10.31 | 0 | | -0.05 | -0.05 | -0.08 | -0.10 | -0.13 | -0.13 | -0.13 | | ¦µ+1.5ˇă | 20 | 25 | 25 | 20 | 20 | 20 | 20 | | rb | 0.35 | 0.35 | 0.41 | 1.19 | 1.60 | 1.98 | 3.96 | | rt | 0.13 | +0.05 | 0.30 | +0.05 | 0.64 | +0.05 | 1.17 | +0.136 | 1.60 | +0.13 | 2.39 | +0.13 | 3.18 | +0.13 | | 0 | 0 | 0 | 0 | 0 | 0 | 0 | | 2¦Â | 0.508 | 0.508 | 0.508 | 0.762 | 1.372 | 2.794 | 3.048 | | | |  |  | | | 1. Pulley Types

2. Dimension, Tolerances & Technical Parameters

3. Dimension of Pulley Tooth Flank Width

4. Order Attention | 1, the type of synchronous belt round

2, tooth-size, tolerance and technical parameters

3, various models of synchronous belt tooth surface width size table

4, ordering notes

| Arc Gear types:

1) single-cylinder gear circular arc gear and double arc gear.

2) single-arc gear contact line intensity ratio under the same conditions involute gear, but bending strength than involute line low.

3) arc gear used mainly in the soft or hardened tooth surface, which tends to be used when using Hardened dwarf gear.

| Arc gear drive design steps:

1) simplify the design: According to the transmission gear transmission power, input speed, transmission ratio and other conditions to determine center distance, modulus, and other key parameters. If the center distance modulus known, can skip this step.

2) calculate the geometric design: design and the basic parameters of gear, and geometry calculation.

3) Strength Check: The basic parameters established, the precise tooth contact strength and flexural strength tooth root check.

4) Check if the requirements are not satisfied with intensity, can be returned.

| Arc gear transmission characteristics:

1) pilot arc Gear meshing transmission, value applicable to helical gear, the gear can not be used directly.

2) relative radius of curvature than involute line, contact involute line intensity than high.

3) changes in the center distance than the sensitivity of the involute. Processing, Cutting depth requirements for higher radial displacement does not allow cutting and careful control of assembly error.

| Single arc Gear

The small convex tooth gear tooth profile work outside in the circular section, tooth profile in the center of circle; large concave tooth gear tooth profile work in the Festival Circle, CenterÂÔĆ«in the tooth profile outside the circle section (Figure 2 single arc Gear Transmission meshing). Due to the large gear tooth profile arc radius p2 slightly larger than the small gear tooth profile radius p1, so when two K tooth profile to the point, its normal line through the node c, the tooth will contact immediately separated, but it is the other end o the tooth profile immediately contacted, or two teeth K1 ©p K'1, K2 ©p K'2 ©p K3 ©p K'3ˇˇ points followed along the line contact meshing. Therefore, the arc gear ©p concave surface of the convex side tooth profile only for instantaneous meshing. A new circular gear in meshing theory is instantaneous point, it Arc Gear also often called point arc meshing gear transmission. After running-gear tooth after tooth profile can actually high gear along with a rather long period of exposure. Arc Gear is characterized by: (1) comprehensive than the radius of curvature of involute gear transmission line much bigger than the strength of its contacts involute gear transmission line of about 0.5 to 1.5 times (2) two teeth meshing line along the direction rolling great speed, easy form of tooth surface oil film, transmission more efficient, usually ranging from 0.99 to 0.995 (3) arc high gear tooth direction along wear uniform, and easy running-in (4) arc cutting gear rootless the phenomenon, it could be the smallest number of teeth less. But from the arc of the Center ©p Gear Cutting helix angle and depth of the great sensitivity of error, the three errors on a greater impact on carrying capacity, so arc gear on the manufacture and installation of high accuracy requirements. In addition, single-arc Gear bending strength, relatively low modulus of the same cutting large and small gear, preparing two different hob.

| Double arc Gear

Working from a Face, the first tooth Au initiative to promote the Department of the Ministry follower of convex tooth left and then to the Department of its convex concave promote each other's Department, so double arc Gear, in theory at the same time there are two contacts , the running-in, in fact there are two such contacts transmission lines, it can be realized more and more of teeth meshing. In addition, because of its greater thickness of the tooth root, not only double arc gear transmission capacity than single-gear transmission arc about 30% higher above, and drive more stable, less vibration and noise, and the same can be matched to the processing hob the two gear. So. High-speed heavy-duty, a double arc Gear replace single-arc Gear trend. | | |

|

|