|

|

|

|

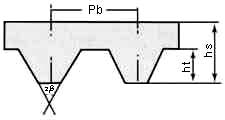

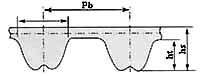

|  |  |  |  | | | | | |  |  | | | | | Please click "Details" for further information | | Type | Pitch

Pb(mm) | Tooth height

ht(mm) | Belt thickness

hs(mm) | Angle β° | Details | | MXL | 2.030 | 0.51 | 1.14 | 40 | Details | | XL | 5.080 | 1.27 | 2.30 | 50 | Details | | L | 9.525 | 1.91 | 3.60 | 40 | Details | | H | 12.70 | 2.29 | 4.30 | 40 | Details | | XH | 22.225 | 6.35 | 11.20 | 40 | Details | | XXH | 31.750 | 9.53 | 15.70 | 40 | Details | | T2.5 | 2.5 | 0.7 | 1.30 | 40 | Details | | T5 | 5 | 1.20 | 2.20 | 40 | Details | | T10 | 10 | 2.50 | 4.50 | 40 | Details | | T20 | 20 | 5.00 | 8.00 | 40 | Details | | AT5 | 5 | 1.20 | 2.70 | 50 | Details | | AT10 | 10 | 2.50 | 5.00 | 50 | Details | | AT20 | 20 | 5.00 | 8.00 | 50 | Details | | Arc Teeth Industrial Rubber Timing Belt

|

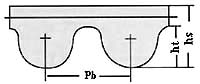

| | | Please click "Details" for further information |  | | | HTD | | |  | | STPD/STS | | |  | | RPP/HPPD | | | | | | |  | | |

| Industrial synchronous belt use raw materials:

High-quality Japanese imports of neoprene as the main raw materials, distribution of the supplies, a variety of different uses; skeleton materials for the Japanese import quality glass fiber cord; tooth surface with nylon 66 high elastic fabrics do protection. With dynamic flexor around good, good anti-cracking properties, ozone excellent performance, anti-aging, heat resistance, oil resistance, abrasion-resistant characteristics.

|

| Industrial synchronous belt features:

With synchronous belt drive is the use of tooth and tooth meshing with the impetus to pass a new type of transmission mode. With accurate synchronous transmission function, do not need lubrication and no slip, no pollution, less noise, transmission efficiency of 0.98, the speed ratio range up to 1:10, allowing wire speed up to 50 m / s, the transmission rate from several hundred watts to the hundreds of kilowatts, suitable for multi-axis drive.

Neoprene synchronous belt widely used in the textile, automobile, chemical fiber, tobacco, paper, printing, chemical mechanical equipment; In recent years, mining and metallurgy, iron and steel machinery, medical equipment demand is growing.

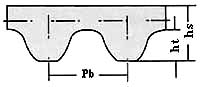

Double-tooth and tooth pitch synchronous belt of single tooth synchronous belt and the same. If the arrangement with the teeth and separable:

DA-type (with a symmetrical arrangement tooth, see figure a; DB-type (with staggered teeth were arranged location, see Figure b).

|

| T-synchronous belt drive system in exactly the same, he can improve the efficiency of the engine so that the engine can be smooth and quiet operation, more capable.

When attention to the purchase of industrial products synchronous belt surface clean, no twisted belt, filled with teeth.

Industrial synchronous belt use Note:

Synchronous belt products need no twists and turns to avoid injury skeleton material impact belt strength.

Scratch synchronous belt products need no belt, belt early so as to avoid damage.

Synchronous belt products to avoid chemicals (especially the strong oxidizing acid, such as concentrated sulfuric acid, etc.) contact.

Synchronous belt and oil products to avoid, long-term exposure to water.

Replacement synchronous belt, the belt tension to be reduced to a minimum, can be taken out, no-synchronous belt high tension in the circumstances, the use of non-professional tools rigid prized down.

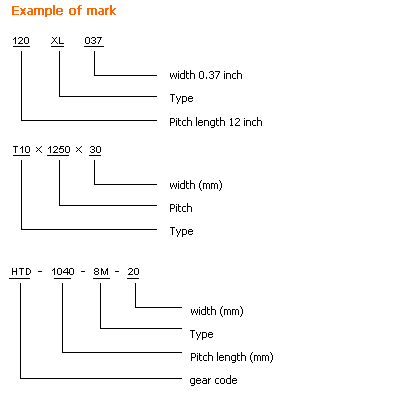

| | | | Ordering attention. |

| * We can produce belts as your supplied sample.

* We can produce particular type or functione belts(such as anti-static electricity,poison-free) as clients’request. | | |

[Back] |

|